Electroplating Power Supplies and plating rectifiers: Precision and Efficiency and more!

Introducing Kirchner Galvanik, the leading partner in electroplating power supplies and electroplating rectifiers that incorporate cutting-edge features tailored to today's dynamic needs.

Electroplating Power Supply: Beyond Precision

At the heart of this perfection is an advanced electroplating power supply. We've designed and engineered them to be the leading edge. Equipped with high-precision, current-regulating plating rectifiers, our power supplies ensure up to 0.5% plating accuracy. The result? Electroformed parts with unmatched precision and consistency.

|

|

|

|

Kirchner offers single and multi-channel electroplating rectifiers designed for various electroplating applications, including diamond tools and electronic products.

![]() Single canal electroplating rectifiers

Single canal electroplating rectifiers

![]() Multi canal electrolating rectifiers

Multi canal electrolating rectifiers

![]() Laboratory power supplys

Laboratory power supplys

It features products with specifications ranging from 0.4A to 50A and voltages up to 30V, suitable for small workpieces to high-demand applications.

Highlighted features include high precision constant current, the ability to plate different parts simultaneously, and models designed for specific needs like dental tools, laboratory uses, and high-power demands.

our plating rectifiers emphasizes customization, precision, and efficiency in electroplating processes.

Electroplating Rectifiers Data Sheet PDF

Smart features for today's electroplating needs. All of our electroplating rectifiers have:

![]() Amp-hour meter: (Ah-Meter): Monitor and manage your plating sessions with a built-in ampere-hour meter designed for professionals who demand real-time data.

Amp-hour meter: (Ah-Meter): Monitor and manage your plating sessions with a built-in ampere-hour meter designed for professionals who demand real-time data.

![]() Timer function: Our plating power supplies come with a unique feature that maintains potential power output even after a scheduled period of time has elapsed. No interruptions, just seamless operation.

Timer function: Our plating power supplies come with a unique feature that maintains potential power output even after a scheduled period of time has elapsed. No interruptions, just seamless operation.

![]() Multi channel power supply: Increase the efficiency of your setup with our Multi-Channel Rectifier, an electroplating power supply designed for simultaneous plating operations.

Multi channel power supply: Increase the efficiency of your setup with our Multi-Channel Rectifier, an electroplating power supply designed for simultaneous plating operations.

![]() Power supplies for Nickel Bond Diamond Tools Dive into niche plating with our nickel-bonded diamond tool plating rectifiers that ensure pristine finishes and extended tool life.

Power supplies for Nickel Bond Diamond Tools Dive into niche plating with our nickel-bonded diamond tool plating rectifiers that ensure pristine finishes and extended tool life.

![]() Monitoring and safety: Our plating rectifiers are equipped with real-time short and open circuit alerts to ensure your tools are plated properly.

Monitoring and safety: Our plating rectifiers are equipped with real-time short and open circuit alerts to ensure your tools are plated properly.

![]() Energy-Efficient Electroplating Power Source: With a focus on sustainable operations, our equipment is designed to be energy efficient, ensuring optimal performance with minimal energy consumption.

Energy-Efficient Electroplating Power Source: With a focus on sustainable operations, our equipment is designed to be energy efficient, ensuring optimal performance with minimal energy consumption.

Why Kirchner power supplies and rectifiers?

Unmatched Expertise: 20 years in the electroplating industry has made us a partner with expertise that translates into products that are ahead of their time.

Relentless Commitment to Quality: Every electroplating rectifier for electroplating, is a tested and calibrated. All of our rectifiers undergo rigorous quality checks.

Customer First: At Kirchner Galvanik, relationships are for years. Our team is always ready to assist you and ensure that your electroplating process is seamless.

Innovation at the Heart: Our R&D teams are at the forefront of innovation, ensuring that our electroplating power supplies remain at the forefront of technology.

In essence, Kirchner Galvanik isn't just a supplier, but a partner committed to driving your plating process to absolute perfection. Our advanced features and commitment to quality ensure that with every layer you add, you're creating a masterpiece. With Kirchner Galvanik, you're not just plating, you're building the future.

KSQproduction - Software for electroplating rectifier

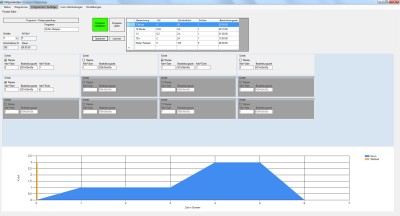

KSQproduction: Advanced Software for Precision Electroplating Control

KSQproduction: Advanced Software for Precision Electroplating Control

In the field of electroplating, precision and control are of the utmost importance. The KSQproduction software represents a significant leap forward in plating technology, offering a comprehensive solution designed to enhance the capabilities of modern plating equipment. This innovative software package is designed to optimize the application of precise finishes, ensuring unparalleled quality in the production of plated components.

At its core, KSQproduction provides real-time monitoring of both the plating rectifier and the entire electroplating process. This continuous oversight allows operators to maintain strict control over all aspects of the plating operation, resulting in consistently flawless results. The software's intuitive interface allows users to easily fine-tune plating parameters, resulting in increased consistency, superior quality and improved efficiency throughout the plating process.

Key features of KSQproduction:

- Multi-Rectifier Control:

The software provides the ability to control up to 24 KSQ plating rectifiers simultaneously from a single PC. This centralized management system streamlines operations in large plating facilities and allows for efficient monitoring of multiple plating lines. - Advanced Production Order Management:

KSQproduction facilitates the transfer and processing of complex production orders. Each job can contain up to 12 individual power programs, complete with customizable steps and ramps. This granular control allows for the creation of highly specific plating profiles tailored to different component requirements. - Extended plating times:

The software supports plating times of up to 1000 hours for each individual step within a plating program. This extended capability is particularly valuable for thick deposits or specialized plating processes that require longer exposure times. - Comprehensive Data Recording:

KSQproduction maintains detailed records for each plating rectifier, including current, voltage, production order details, and the specific current program used. This wealth of data allows thorough analysis and optimization of plating processes over time. - Customizable Current Programs:

Users can define and save custom plating programs, creating a library of preset plating profiles for different parts and finishes. This feature significantly reduces setup time and ensures consistency across production runs. - Visual Data Presentation:

The software presents production data in clear, easy-to-interpret graphs. These visual aids allow operators to quickly assess the status of ongoing plating processes and identify any deviations from desired parameters. - Detailed Production Documentation:

KSQproduction generates comprehensive documentation of production parameters, traceable to each individual work order. This feature is invaluable for quality control, process validation and regulatory compliance. - User-friendly interface:

The software's intuitive design ensures that operators of all skill levels can effectively navigate its features, minimizing the learning curve and maximizing productivity. - Real-time Alerts and Notifications:

KSQproduction can be configured to send alerts when plating parameters deviate from preset ranges, allowing for immediate corrective action and minimizing the risk of defective products.

By implementing KSQproduction, plating operations can expect significant improvements in product quality, process efficiency and overall operational control. The software's ability to accurately manage complex plating profiles ensures that even the most demanding finishing requirements can be consistently and reliably met.

Whether you're a small plating shop or a large industrial facility, KSQproduction provides the tools and capabilities you need to stay at the forefront of electroplating technology. With its comprehensive feature set and easy-to-use design, this software is an essential investment for any operation looking to optimize their plating processes and deliver superior finished products.

Kirchner KSQproduction rectifier Electroplating Software

x 0,4A / 0-12V

x 0,4A / 0-12V  x 25A / 0-10V

x 25A / 0-10V  Multi-channel power supply

Multi-channel power supply  German

German